Why Your Garage Roof Deserves Better Than a Slow Leak

Corrugated garage roof replacement is a project that can solve persistent leaks, improve curb appeal, and add decades of protection. Whether you’re dealing with rust, loose fasteners, or water damage, the project involves removing old panels, inspecting the deck, installing underlayment, and securing new corrugated metal sheets.

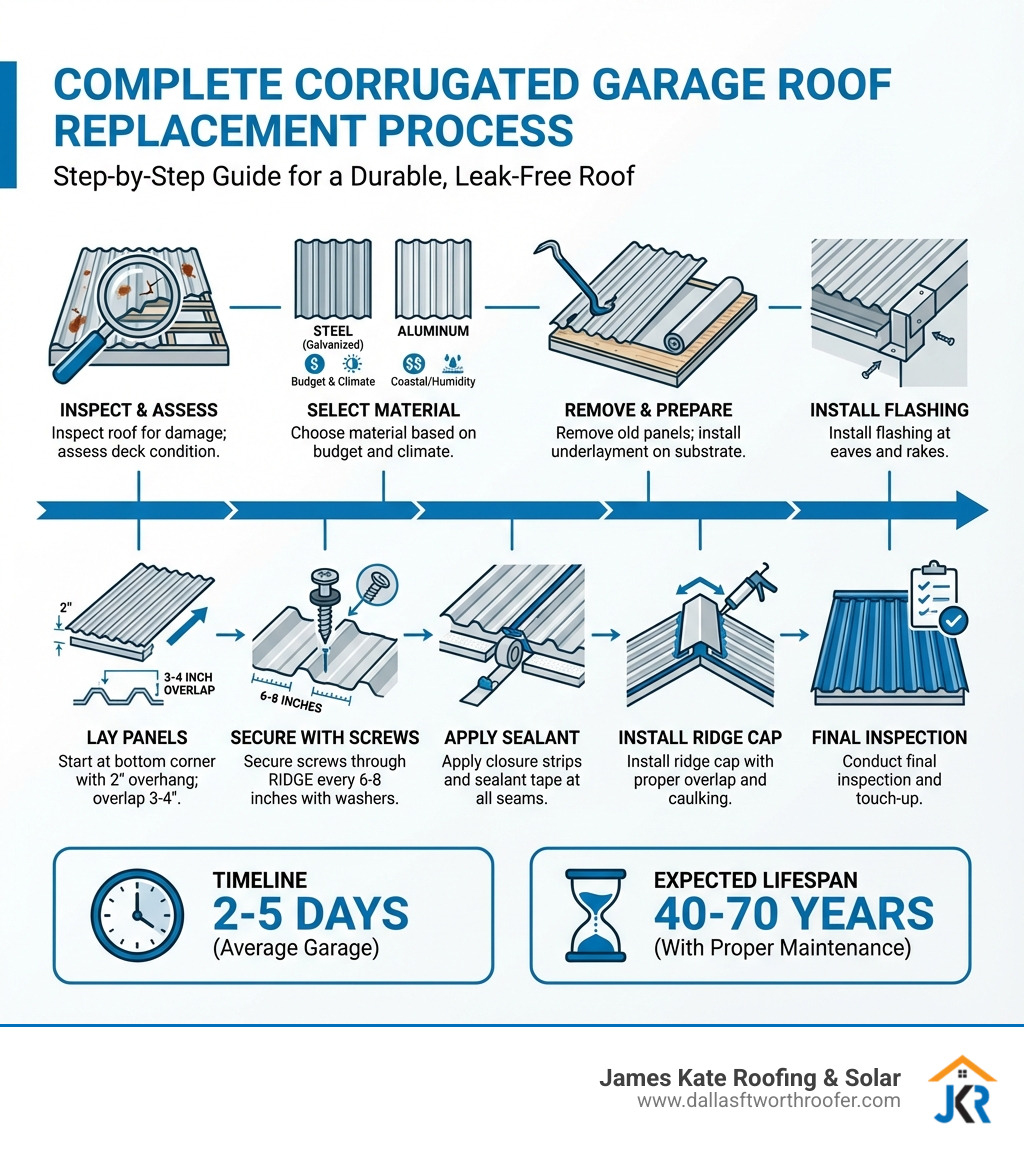

Quick Answer: Key Steps for Corrugated Garage Roof Replacement

- Assess the damage – Check for rust, leaks, loose screws, and structural issues

- Choose your material – Galvanized steel or aluminum panels (typically 26-28 gauge)

- Gather tools and materials – Drill, angle grinder, underlayment, flashing, closure strips, screws with washers

- Prepare the roof – Remove old panels, inspect and repair deck, install underlayment

- Install new panels – Start at the eave, overlap by 3-4 inches, secure every 6-8 inches

- Seal properly – Use closure strips, sealant tape, and caulk at all overlaps and ridge caps

- Maintain regularly – Inspect fasteners, clean debris, touch up scratches

For homeowners in the Dallas-Fort Worth area dealing with a leaking garage or considering an upgrade, this guide is for you. A corrugated metal roof can last 40-70 years when installed correctly—far longer than traditional asphalt shingles. Metal roofing reflects solar heat, cuts cooling costs, resists extreme weather, and is often made from recycled materials.

But here’s the catch: proper installation matters. Exposed fasteners are the Achilles’ heel of corrugated roofs. If screws aren’t seated correctly, placed in the wrong spot (like the valley instead of the ridge), or lack proper washers, you’ll face leaks. The corrugated design is brilliant for strength and water runoff, but only if every overlap is sealed and every panel is square to the building.

I’m Dustin Eatman, owner of James Kate Roofing & Solar. I’ve spent years helping DFW property owners with corrugated garage roof replacement projects, from diagnosing failing fasteners to ensuring proper flashing. Whether you’re tackling this as a DIY project or hiring a pro, this guide will walk you through the process to keep your garage dry for decades.

Is It Time to Replace Your Corrugated Garage Roof?

Your garage roof takes a beating protecting your property from harsh Texas weather. Even robust corrugated panels show wear over time, and recognizing the signs early can save you from costly damage. The wave-like pattern adds structural strength, promotes water runoff, and provides excellent weather resistance, making it a practical choice for DFW garages.

However, no roof lasts forever. If you’re noticing issues, it might be time for a corrugated garage roof replacement. We offer comprehensive roof inspection services to help you decide.

When to Repair vs. Replace

Deciding to repair or replace can be tough. Minor issues like a loose screw or a small dent can often be repaired. However, for widespread problems like multiple leaks, significant rust, or a sagging deck, replacement is the more cost-effective long-term solution. Temporary fixes are often insufficient as underlying problems persist. For more information, explore our roof repair services.

Key Signs Your Corrugated Roof Needs Replacement

Here are the signs that your corrugated garage roof needs a full replacement:

- Visible Rust Spots and Corrosion: Galvanized steel can rust where coatings are damaged. Spreading rust compromises the panel’s integrity.

- Multiple or Persistent Leaks: While a single leak may be repairable, multiple leaks indicate the roof’s overall integrity is compromised.

- Cracked or Brittle Panels: Older panels can become brittle and crack from sun exposure and age, leaving your garage vulnerable.

- Loose or Missing Screws/Fasteners: Fasteners can loosen over time from thermal expansion, allowing water in. If many are loose, the roof’s attachment is compromised.

- Significant Storm Damage: Severe storm damage from DFW’s hail and high winds, such as dents, punctures, or uplifted panels, often requires a full corrugated garage roof replacement.

- Sagging Roof Deck: A sagging deck indicates structural problems that must be fixed before replacing the panels.

- Plant Growth on the Roof: Plant growth on the roof or in gutters indicates moisture retention and potential degradation.

Planning Your Project: Materials, Costs, and Codes

Before installation, it’s important to choose the right materials, create a budget, and understand local regulations.

Choosing Your Corrugated Roofing Material

Metal is the primary choice for a corrugated garage roof replacement, offering excellent durability and longevity.

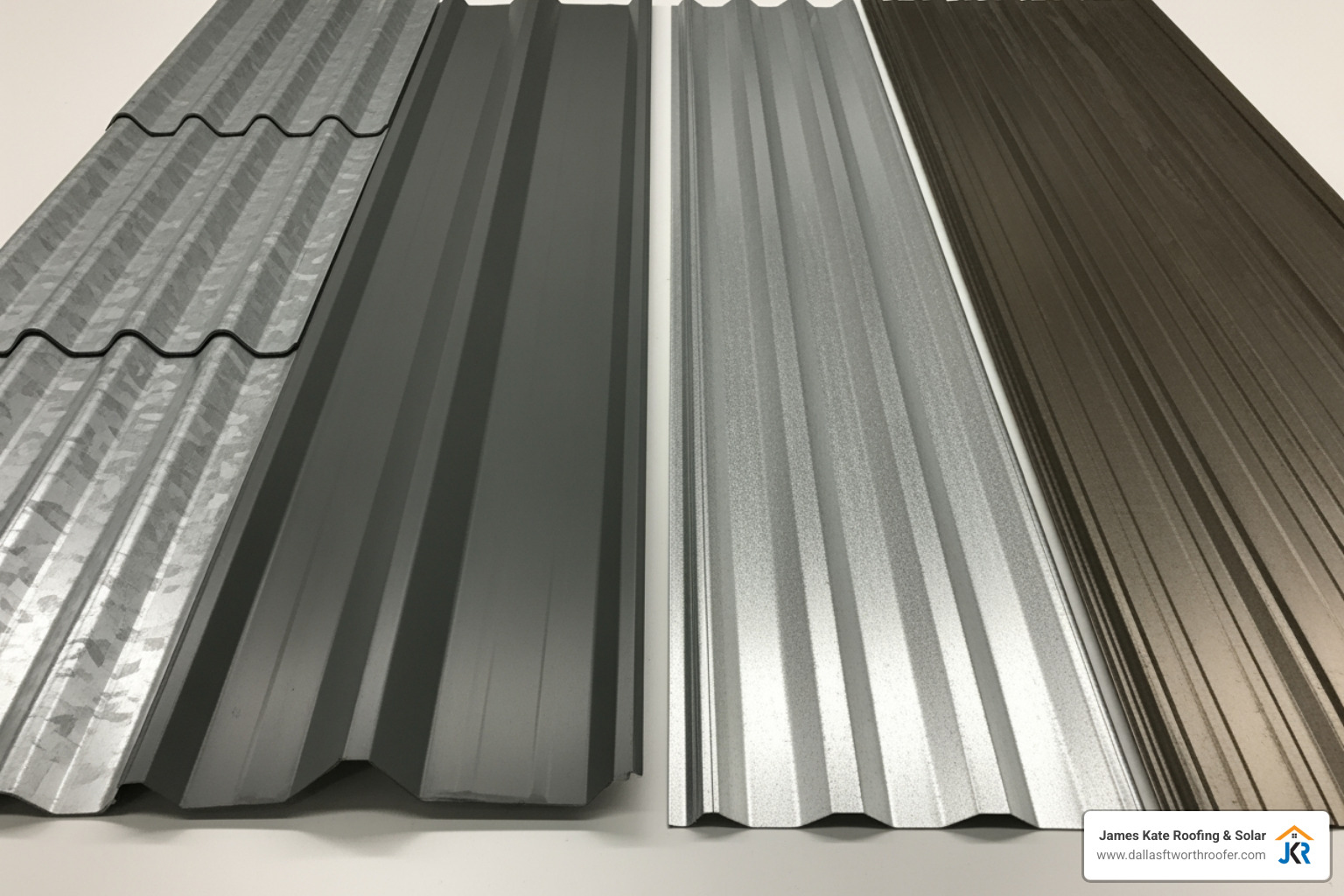

- Galvanized Steel: This is the most common and cost-effective option. These steel panels are coated with zinc to prevent corrosion, offering a balance of strength and affordability. They can rust if the coating is damaged. For garages, 26-28 gauge is typical.

- Aluminum: Lighter than steel, aluminum is naturally rust-resistant and can last up to 50 years. However, it’s more prone to denting from impacts like hail.

- Other Corrugated Options: Less common options include bitumen-based panels, which are affordable but need more support, and PVC or polycarbonate panels, which are less durable than metal.

Here’s a quick comparison of common corrugated metal options:

| Material | Cost (per sq ft) | Lifespan | Durability | DIY-Friendliness |

|---|---|---|---|---|

| Galvanized Steel | $16–$22 | 40-70 years | Good; strong, but can rust if coating is compromised; susceptible to dents. | Good |

| Aluminum | $17–$24 | 40-50 years | Excellent; naturally rust-resistant, but more prone to denting than steel. | Good |

Did you know that metal roofs are environmentally friendly? Many metal roofs are made of 30%–60% recycled metal, and they are 100% recyclable at the end of their long life. For more detailed information on metal roofing, explore our guide to metal roofing.

Understanding the Cost of Corrugated Garage Roof Replacement

The cost of a corrugated garage roof replacement varies, but it’s a worthwhile investment. Metal roofing generally costs $14–$40 or more per square foot. While the upfront cost is higher than asphalt, metal roofs last 40+ years, far longer than asphalt’s 20–30 year lifespan.

Here’s what influences the total cost:

- Material Costs: Different metals have different price points. The gauge (thickness) of the metal also plays a role.

- Labor Costs: Labor often accounts for 60% of the total cost. Professional installation ensures proper technique, safety, and longevity.

- Roof Size and Complexity: Larger or more complex roofs with multiple angles or penetrations cost more due to increased material and labor.

- Roof Pitch: A steeper pitch can increase labor costs due to safety needs and installation difficulty.

- Underlayment and Deck Condition: Deck repairs or premium underlayment will add to the cost.

- Removal of Old Roof: Removing the old roof, especially if it contains hazardous materials like asbestos, adds costs for safe disposal.

Despite the upfront investment, metal roofs offer excellent long-term value. According to the 2024 Cost vs. Value Report, the average return on investment for metal roof replacement is 48%. This means nearly half of your investment could be recouped in increased property value. If you’re concerned about the initial outlay, we can help you with financing options.

DIY vs. Hiring a Pro for Your Corrugated Garage Roof Replacement

Deciding between DIY and hiring a pro for your corrugated garage roof replacement depends on several factors:

DIY Considerations:

- Skill Level Required: While often considered DIY-friendly for garages, this project requires roofing knowledge, precision, and proper sealing techniques.

- Safety Risks: Working on any roof involves significant fall risks. You’ll need ladders, scaffolding, and proper safety gear.

- Tool Requirements: Specialized tools like an angle grinder and electric drill are required, and rental costs can add up.

- Time Commitment: A DIY project takes significantly longer than professional installation.

- Building Codes: You must comply with local DFW building codes, and permits are often required.

Hiring a Professional:

- Expertise and Efficiency: Pros have the experience and tools to complete the job safely and efficiently, preventing future leaks.

- Warranty: Reputable contractors offer workmanship warranties, and manufacturers provide material warranties.

- Safety: Professionals follow strict safety protocols, minimizing risks.

- Code Compliance: A pro ensures your new roof meets all local building codes and handles any necessary permits.

- Long-Term Value: Proper installation by an experienced team ensures your investment lasts for decades.

While DIY saves on labor, the complexities and safety risks often make hiring a pro a more reliable and cost-effective choice. For expert assistance with your corrugated garage roof replacement, consider our professional roof replacement and installation services.

Your Step-by-Step Guide to Corrugated Garage Roof Replacement

Whether you’re doing it yourself or watching a pro, here’s a step-by-step breakdown of the process. Safety always comes first!

Tools, Materials, and Roof Preparation

Gather all tools and materials before you begin. Safety gear is non-negotiable.

Essential Tools:

- Angle grinder or tin snips/nibbler.

- Electric drill with a 3/16 inch (4.8 mm) drill bit.

- Chalk line.

- Roofing nailer or hammer.

- Tape measure and marker.

- Caulking gun.

- Safety gear: Heavy-duty gloves, eye protection, hearing protection, sturdy work boots, and fall protection.

Materials Needed:

- Corrugated panels (galvanized steel or aluminum, 26-28 gauge).

- Underlayment (roofing felt or synthetic).

- Flashing (eave, rake, ridge cap).

- Sealant tape (butyl tape) and roofing sealant/caulk.

- Closure strips.

- Roofing screws (1.5-inch wood screws with neoprene washers).

Roof Preparation:

- Clear the Area: Remove anything that could be damaged by falling debris.

- Remove Old Roofing: Carefully remove the old panels. If they contain asbestos, consult a professional for safe removal.

- Inspect the Roof Deck: Crucially, inspect the deck for damage, rot, or weakness. Repair or replace compromised sections. Ensure the deck is clean, dry, free of nails, and square.

- Lay the Underlayment: Roll out your chosen underlayment horizontally from the eaves up, overlapping each strip by 1–2 inches. Secure it with a roofing nailer or staples. This provides a secondary moisture barrier.

Installing the Corrugated Panels

With the prep work done, it’s time for the main event!

- Install Flashing: Secure the eave flashing along the bottom edge, overlapping sections by 0.25–0.5 inches and nailing every 16 inches. This directs water into the gutters.

- Apply Sealant and Closure Strips: Lay a strip of sealant tape on the eave flashing, then place closure strips along the sealant. These block wind, rain, and insects.

- Lay the First Panel: Apply sealant on the closure strip. Place the first panel at a bottom corner with a 2-4 inch overhang. Ensure the panel is square using a chalk line.

- Pre-Drill and Secure the First Panel: Pre-drill holes on the ridges (high points), not the valleys, to prevent water pooling. Space holes every 6-8 inches horizontally and 2 feet vertically. Drive roofing screws with washers until the head just meets the panel.

- Overlapping Panels: Overlap subsequent panels by 3–4 inches (one corrugation). Apply a bead of sealant along the overlap before screwing them together.

- Working Towards the Ridge: Continue installing rows, overlapping the lower row by about 4 inches to ensure proper water runoff.

- Installing the Ridge Cap: Once all panels are installed, install the ridge cap. Overlap sections by 3-4 inches, apply sealant at overlaps, and secure with screws through the ridges.

For more detailed instructions, you can refer to resources like How to Install Corrugated Metal Roofing.

Ensuring a Long-Lasting and High-Performing Roof

Your new roof looks great, but the work isn’t over. To ensure your investment lasts, focus on proper sealing, regular maintenance, and performance improvements.

Proper Sealing to Prevent Leaks

Effective sealing is critical to preventing leaks and is often a weak point in poor installations.

- Sealant Tape and Closure Strips: As mentioned in installation, sealant tape and closure strips are the first line of defense at eaves and rakes, blocking wind and water.

- Caulking Overlaps: Apply high-quality roofing sealant along all panel overlaps (side and end) to create a watertight seal.

- Waterproof Washers: The neoprene washers on roofing screws create a watertight seal. Ensure they are properly seated—not too tight or too loose.

- Ridge Cap Sealing: The ridge cap is a common leak point. Apply ample sealant at all overlaps.

- Flashing Installation: Correctly installed flashing around penetrations and at edges is critical for diverting water.

We’ve seen how crucial these details are. As experts in the DFW climate, we understand the challenges that test a roof’s seals. We specialize in addressing common issues with corrugated metal roofs, especially related to fasteners and sealing.

Maintenance to Prolong Roof Life

A little routine care goes a long way in maximizing the lifespan of your corrugated garage roof replacement.

- Regular Inspections: Periodically and safely inspect your roof for damage, loose fasteners, or debris, especially after major storms.

- Cleaning Debris: Clear debris from the roof and gutters to prevent water damming. Clean with water and mild detergent; avoid abrasive cleaners.

- Checking Fasteners: Tighten loose screws and replace any degraded washers over time.

- Touching Up Scratches: Use touch-up paint on any scratches to prevent rust, especially on galvanized steel.

- Gutter Maintenance: Keep gutters clean to prevent water backup and premature roof wear.

Consistent maintenance helps ensure your roof performs optimally for its full 40-70 year lifespan. If you need assistance, we’re here to help; you can schedule your roof maintenance with us.

Improving Insulation and Reducing Noise

Common concerns about metal roofs include noise and temperature. However, modern installation techniques can mitigate these issues.

- Adding Insulation Under the Deck: Installing insulation under the roof deck improves thermal performance, keeping the garage more comfortable and reducing energy costs in climate-controlled spaces.

- Using Insulated Panels: Pre-insulated corrugated panels are also available, offering superior thermal and acoustic performance.

- Condensation Control: In humid climates, condensation can be an issue. Proper attic ventilation, a vapor barrier, and insulation under the deck are crucial to prevent it.

- Noise-Dampening Underlayment: A high-quality synthetic underlayment can also help dampen sound.

- Using Thicker Gauge Metal: A thicker gauge metal (e.g., 24 gauge) can offer better noise reduction and durability.

The myth that metal roofs are noisy in rain is largely unfounded with proper installation. The roof deck, underlayment, and insulation work together to dampen sound.

Frequently Asked Questions about Garage Roof Replacement

Here are answers to common questions about corrugated garage roof replacement.

Can I install a corrugated roof over my old shingles?

Yes, you can often install a metal roof over existing shingles, saving on tear-off costs. First, inspect the roof deck for damage. If it’s sound, you can proceed, but always check local DFW building codes for restrictions and use a proper underlayment between the old shingles and new metal panels.

How long does a corrugated metal garage roof last?

A professionally installed corrugated metal garage roof can last an impressive 40 to 70 years. Lifespan depends on the metal type, climate, installation quality, and maintenance. With proper care, it’s a very long-lasting solution.

Are metal garage roofs noisy in the rain?

This is a common misconception. When properly installed, modern metal roofs are generally no noisier than other types of roofs during rain. The sound-dampening effect comes from the roof deck, underlayment, and any insulation. An insulated garage will barely register the sound of rain on a metal roof, making the noise negligible.

Conclusion

A corrugated garage roof replacement is an investment in your property’s longevity, function, and appeal. By choosing the right materials and ensuring proper installation, you get a dry, protected space for decades. The long-term benefits of a durable, weather-resistant metal roof—including increased property value and energy efficiency—offer invaluable peace of mind.

For a professional assessment and a commitment to honesty and integrity on your DFW roofing project, trust the experts at James Kate Roofing & Solar. We’re a family-owned company dedicated to providing top-tier solar services, backed by GAF President’s Club recognition and a 25-year workmanship warranty. Contact us today for a free estimate and let us help you protect what matters most.