Why Composite Shingle Installation Matters for Your Home

Composite shingle installation involves applying durable, multi-layered roofing shingles to protect your home and improve its curb appeal. These shingles are typically made from asphalt, fiberglass, and recycled materials.

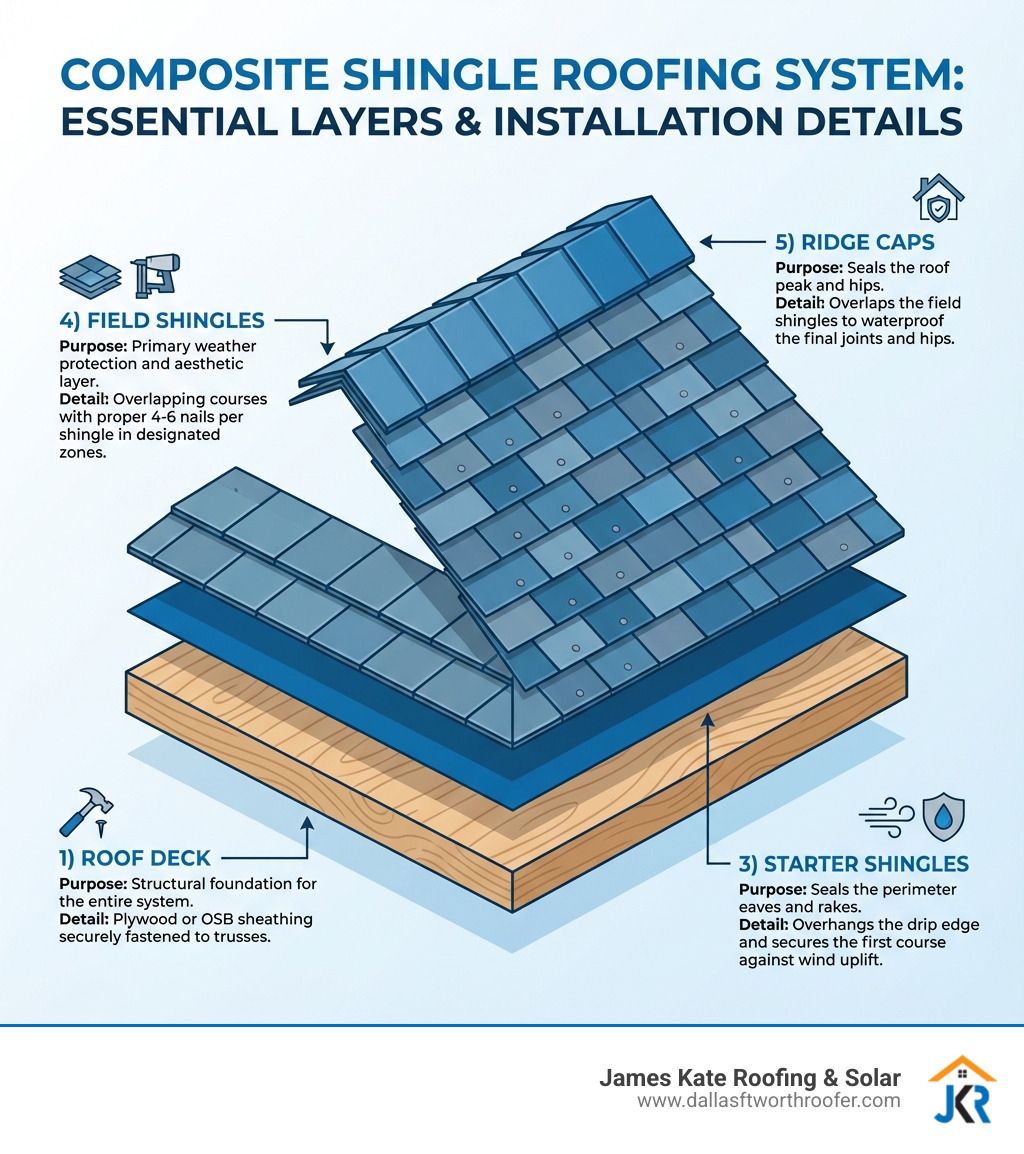

Key Steps for Composite Shingle Installation:

- Prepare the Roof Deck: Remove old shingles, inspect for damage, and ensure a clean, solid surface.

- Install Underlayment and Flashing: Apply a waterproof barrier and flashing to vulnerable areas.

- Lay Starter Course: Install starter shingles along the eaves for proper sealing.

- Install Field Shingles: Work bottom-up, staggering joints and using 4-6 nails per shingle in the designated nailing zone.

- Finish with Ridge Caps: Seal the roof’s peak and conduct a final inspection.

Why It Matters: A properly installed composite roof can last 40-50 years, nearly double the lifespan of traditional asphalt shingles. The quality of the installation directly impacts your roof’s ability to withstand wind, rain, and hail, making correct technique essential.

While composite shingles offer benefits like durability and styles that mimic slate or wood, none of it matters if the installation is flawed. Your roof is a complete system—deck, underlayment, flashing, and shingles—and each part must be installed correctly for the whole system to perform as designed. Laying new shingles on a damaged deck might look fine initially, but it won’t last.

I’m Dustin Eatman, owner of James Kate Roofing & solar in the Dallas-Fort Worth area. I’ve managed hundreds of composite shingle installation projects, navigating Texas weather and ensuring manufacturer warranty compliance. I know what it takes to build a roof that lasts.

Before You Begin: Planning for a Composite Shingle Installation

Before we even think about climbing onto the roof, a successful composite shingle installation begins with meticulous planning. This section covers the essential groundwork, from understanding the material to gathering tools and preparing your roof deck for a successful project.

Understanding Composite Shingles: Materials, Benefits, and Value

Composite shingles, also known as architectural or laminate shingles, are a modern roofing solution engineered for performance and style. They are made from a blend of materials, typically a heavy fiberglass mat coated with asphalt and ceramic granules. Some also include recycled materials, allowing them to mimic slate, wood, or clay tiles without the high cost and maintenance.

Key Benefits of Composite Shingles:

- Longevity & Durability: They last significantly longer than traditional shingles and offer excellent resistance to cracking, chipping, and extreme weather like high winds and hail.

- Curb Appeal: Available in various textures and colors, they can replicate high-end looks like slate or wood shakes to improve your home’s aesthetic.

- Eco-Friendly: Many options include recycled content, and their long lifespan reduces replacement frequency and landfill waste.

- Lightweight: They are lighter than slate or clay, often eliminating the need for structural reinforcement during installation.

- Low Maintenance: Composite roofs are resistant to moisture, pests, and sun-fading, requiring minimal upkeep for decades.

Lifespan and Long-Term Value

Composite shingles are designed to last 40 to 50 years, nearly double the 20-30 year lifespan of traditional asphalt shingles. While their upfront cost is about 20% higher, their extended life and superior durability mean fewer replacements and repairs over time. This makes them an excellent long-term investment, offering a lower total cost of ownership and higher property value.

For a deeper dive, check out our resource: More on composite asphalt shingles.

Here’s a quick comparison:

| Feature | Composite Shingles (Architectural) | Traditional Asphalt Shingles (3-Tab) |

|---|---|---|

| Lifespan | 40-50 years | 20-30 years |

| Durability | Excellent (wind, hail, impact) | Good (basic weather resistance) |

| Aesthetics | Dimensional, mimics natural looks | Flat, uniform |

| Material Cost | Higher (approx. 20% more) | Lower |

| Long-Term Value | Excellent (less frequent replacement, fewer repairs) | Good (more frequent replacement, potential for more repairs) |

| Weight | Heavier, but still lighter than tile/metal | Lighter |

Essential Tools, Materials, and Safety Gear

Proper tools, materials, and safety gear are critical for a successful composite shingle installation.

Essential Tools:

- Roofing nailer and air compressor

- Hammer and utility knife (with extra blades)

- Tape measure and chalk line

- Roof shovel and caulk gun

- Framing square and ladder

- Broom, trash cans, and tool belt

- Magnetic sweeper (for nail cleanup)

Essential Materials:

- Composite shingles, starter shingles, and ridge caps

- Synthetic underlayment and leak barrier (ice-and-water shield)

- Drip edge and various flashing

- Corrosion-resistant roofing nails (11 or 12 gauge, 3/8″ head, long enough to penetrate the deck 3/4″)

- Roofing cement

Safety Gear:

Safety is non-negotiable. Always use:

- Safety harness and fall protection system

- Hard hat and eye protection

- Gloves and rubber-soled shoes

- Respirator (if needed for dust/chemicals)

Safety, Estimating, and Roof Deck Preparation

This groundwork is crucial for a successful project.

Safety Precautions:

- Never work on a wet, icy, or windy roof.

- Use a stable, properly secured ladder that extends 3 feet above the eave.

- Always use a safety harness and fall protection, especially on steep slopes.

- Be aware of your surroundings and keep the ground area clear.

- Handle heavy shingle bundles with care.

- Use a magnetic sweeper to clean up fallen nails.

Estimating Materials:

Accurate estimating prevents waste and project delays.

- Measure Roof Area: Calculate the total square footage of all roof planes.

- Calculate ‘Squares’: Divide the total square footage by 100 to find the number of “squares” needed (roofing is sold by the square).

- Factor in Waste: Add 10-15% for waste, cuts, and mistakes (up to 20% for complex roofs).

- Don’t Forget Accessories: Remember to calculate for starter shingles, ridge caps, underlayment, and flashing.

Roof Deck Preparation:

A solid foundation is key to a long-lasting roof.

- Tear Off Old Roofing: We strongly recommend a full tear-off of all old materials down to the bare deck. Shingling over an old roof can hide damage and lead to premature failure.

- Inspect the Deck: Carefully check the wood sheathing for rot, water damage, or soft spots.

- Repair or Replace: Replace any damaged plywood or OSB panels to ensure a solid, flat surface.

- Clean the Surface: Sweep the deck clean of all nails and debris before installing new materials.

For significant structural repairs, we can help: Learn about roof repairs.

The Step-by-Step Guide to Your Composite Shingle Installation

With thorough preparation behind us, we’re ready to dive into the core of the project. Follow these key steps for a professional-quality composite shingle installation, ensuring your new roof is watertight and built to last.

Step 1: Install Underlayment and Flashing

Underlayment and flashing are your roof’s primary defense against water intrusion. The underlayment is a secondary water barrier protecting the roof deck, while flashing seals areas where the roof is penetrated or meets a wall, such as valleys, chimneys, and vents.

Installation Steps:

- Install Drip Edge: Apply metal drip edge along the eaves (under the underlayment) and rakes (over the underlayment) to direct water into the gutters.

- Apply Leak Barrier: In vulnerable areas like eaves, valleys, and around penetrations, install a self-adhering ice and water shield. This is especially important for Texas storms.

- Roll Out Underlayment: Cover the entire roof deck with synthetic underlayment, which is more durable and water-resistant than felt. Start at the bottom and overlap each course according to manufacturer specifications, ensuring it lies flat.

- Flash Critical Areas: Integrate flashing as you go. Use step flashing for walls and chimneys, boots for pipes and vents, and proper valley flashing to ensure these leak-prone areas are secure.

For a visual guide, you can explore resources like this: A guide to flashing techniques.

Step 2: Lay the Starter Course and Field Shingles

Accurate alignment is key to a professional look and proper function. We use chalk lines to ensure every course is straight.

Laying the Starter Course:

The starter course is critical for sealing the eaves against wind and water. We install it along the eave with a 1/4 to 3/4-inch overhang to direct water away from the fascia. The adhesive strip on the starter shingle bonds to the first course of field shingles, creating a strong, watertight seal.

Laying Field Shingles:

- Work Bottom-Up: Always install shingles from the bottom of the roof up to ensure proper water shedding.

- Stagger Joints: Stagger the joints between shingles on each successive course according to the manufacturer’s specified offset. This prevents water from penetrating through vertical seams.

- Follow Nailing Best Practices: Proper nailing is crucial for performance and warranty compliance.

- Use the Nailing Zone: Place nails only within the manufacturer’s designated nailing zone (e.g., “The Zone®” by Malarkey) for maximum wind resistance.

- Use the Right Number of Nails: Use 4 nails per shingle for normal conditions and 6 nails for steep slopes or high-wind areas.

- Ensure Proper Nail Depth: Drive nails flush with the shingle surface. Overdriving can cut the shingle, while underdriving prevents a proper seal. Incorrect nailing can void your warranty.

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s instructions for shingle exposure and overlap to ensure a watertight roof and maintain the warranty.

For more details, refer to manufacturer instructions: Detailed shingle installation instructions.

Step 3: Finish with Ridge Caps and Final Cleanup

The final steps are to seal the roof’s peak and ensure a pristine work site.

Cutting Shingles and Installing Ridge Caps:

We carefully cut shingles to fit snugly around vents, chimneys, and skylights, integrating them with the flashing. Then, we install ridge cap shingles to cover the hips and peak of the roof. This seals the final vulnerable points against water and provides a clean, finished look. We install them starting from the bottom of a hip or the end of a ridge opposite the prevailing wind, overlapping each piece for maximum protection.

Final Inspection and Cleanup:

Our job isn’t done until we’ve performed a final quality check and cleanup.

- Final Inspection: We conduct a meticulous inspection to check for any loose shingles, exposed nails, or other issues, addressing them immediately.

- Cleanup: We remove all debris from the roof, gutters, and property. A magnetic sweeper is used to collect any fallen nails from the ground, ensuring the area is safe for your family, pets, and tires.

Advanced Techniques and Professional Insights

Composite shingle installation might seem straightforward in principle, but understanding the nuances of different roof types and the value of professional expertise can make the difference between a good roof and a great one.

Adapting Installation for Roof Pitch and Complexity

Installation techniques must adapt to the roof’s specific characteristics.

- Low-Slope Roofs (2:12 to 4:12 pitch): Water sheds slowly on low slopes, so a double layer of underlayment or a full self-adhering membrane is required to prevent leaks. Shingles should never be used on slopes below 2:12.

- Steep-Slope Roofs (Over 21:12 pitch): On very steep roofs, we use six nails per shingle instead of four and may apply dabs of asphalt cement under each shingle for extra adhesion. Improved safety measures are critical.

- Complex Roof Features: Roofs with dormers, multiple valleys, or skylights require expert flashing and precise shingle cutting to ensure every intersection is completely waterproof.

DIY vs. Professional Composite Shingle Installation: Weighing the Risks

While a DIY roof installation might seem to save money, the risks are significant.

Risks of a DIY Installation:

- Safety: Roofing is dangerous, with a high risk of falls and injury.

- Voided Warranties: Most manufacturers require installation by a certified contractor to validate their 40-50 year material warranties.

- Costly Errors: Mistakes like improper nailing, poor flashing, or ignoring deck damage can lead to leaks, wind damage, and expensive repairs that negate any initial savings.

- Time: A professional crew can re-roof a home in 1-2 days, while a DIY project can take weeks.

Benefits of Professional Installation:

- Expertise and Efficiency: Professionals have the training, tools, and experience to do the job right and quickly, adhering to local codes and manufacturer specifications.

- Improved Warranties: As a certified installer for brands like GAF, CertainTeed, and Malarkey, James Kate Roofing & solar can offer improved warranty options. Our GAF President’s Club status reflects our commitment to quality.

- Workmanship Guarantee: We back our work with a 25-year workmanship warranty, giving you peace of mind that your investment is protected.

Understanding the value of professional service is key. Learn more here: Find out about professional installation services.

Frequently Asked Questions about Composite Shingles

Can I install new composite shingles over an old roof?

We strongly advise against it. While some codes may permit one layer of overlay, a full tear-off is best practice for a composite shingle installation. Installing over an old roof can hide deck damage, add excessive weight, prevent new shingles from sealing properly, and void manufacturer warranties. A tear-off ensures a clean, solid foundation, allowing your new roof to achieve its maximum 40-50 year lifespan.

How long does it take for new composite shingles to seal?

The thermal sealant on composite shingles is activated by the sun’s heat. In warm, sunny Texas weather, this can take a few days. In cooler or overcast conditions, it may take several weeks. If high winds are expected before the shingles have sealed, hand-sealing with dabs of roofing cement is recommended to prevent wind damage. The manufacturer’s wind warranty only applies after the shingles have fully sealed.

What are the main differences when installing composite vs. traditional asphalt shingles?

While the basics are similar, there are key differences:

- Construction: Composite (architectural) shingles are thicker, multi-layered, and heavier, with a dimensional look. Traditional 3-tab shingles are a single, flat layer.

- Layout: 3-tab shingles require precise alignment of their cutouts. Composite shingles have a more random pattern, focusing on a proper stagger between courses rather than aligning tabs.

- Nailing: Many composite shingles feature a wider, reinforced nailing zone (like Malarkey’s “The Zone®”), which is critical for wind resistance and warranty compliance. This area is narrower on 3-tab shingles.

- Durability: The thicker construction of composite shingles provides superior durability and a much longer lifespan (40-50 years vs. 20-30 years for 3-tab).

Conclusion: A Lasting Investment for Your Home

A successful composite shingle installation is a blend of careful planning, correct technique, and high-quality materials. By following these steps, you can ensure your roof provides decades of protection and improves your home’s curb appeal. From preparing the roof deck and carefully installing underlayment and flashing, to expertly laying starter and field shingles, and finally securing ridge caps, every step contributes to the longevity and performance of your roofing system.

For homeowners in the DFW area seeking a flawless installation backed by honesty, integrity, and a 25-year workmanship warranty, James Kate Roofing & solar provides expert services. We understand the unique challenges of the Texas climate and are committed to delivering a roof that will protect your home for years to come. Ready to ensure your roof is installed right? Schedule your professional roof replacement today.