Why Your Commercial Roof Matters More Than You Think

A commercial roof is more than just a protective covering—it’s a critical building asset that impacts your energy costs, interior environment, and long-term property value. Whether you own a warehouse, office building, retail center, or multi-family property in the Dallas-Fort Worth area, understanding your roofing system helps you make informed decisions about maintenance, repairs, and replacements.

Quick Answer: What is a Commercial Roof?

A commercial roof is a roofing system designed for business, industrial, or multi-tenant buildings. Key differences from residential roofs include:

- Slope: Typically flat or low-slope (¼:12 to 3:12 pitch)

- Materials: Single-ply membranes (TPO, PVC, EPDM), modified bitumen, built-up roofing, or metal

- Size: Often covering large, expansive areas

- Function: Designed for durability, energy efficiency, and minimal maintenance

- Lifespan: 20-50+ years depending on material and maintenance

- Cost: $3-$12 per square foot installed

Commercial roofs differ from residential systems in materials, installation methods, and maintenance requirements. They’re built to withstand foot traffic, support HVAC equipment, and handle water drainage across large, flat surfaces.

This guide walks you through everything you need to know: the layers that make up a commercial roof system, how to choose the right material for your building, what impacts long-term performance, and how to protect your investment through proper maintenance and smart upgrades. You’ll also learn about sustainable options, solar integration, and financing strategies that make sense for your business.

My name is Dustin Eatman, and I’ve spent years diagnosing, repairing, and replacing commercial roof systems across the DFW metroplex. I’ve worked with property managers and business owners to solve drainage issues, stop leaks, extend roof lifespans, and integrate solar—often while navigating insurance claims and minimizing operational disruption. Whether you’re dealing with an aging commercial roof or planning a new installation, I’ll help you understand what matters and what doesn’t.

More info about our commercial services

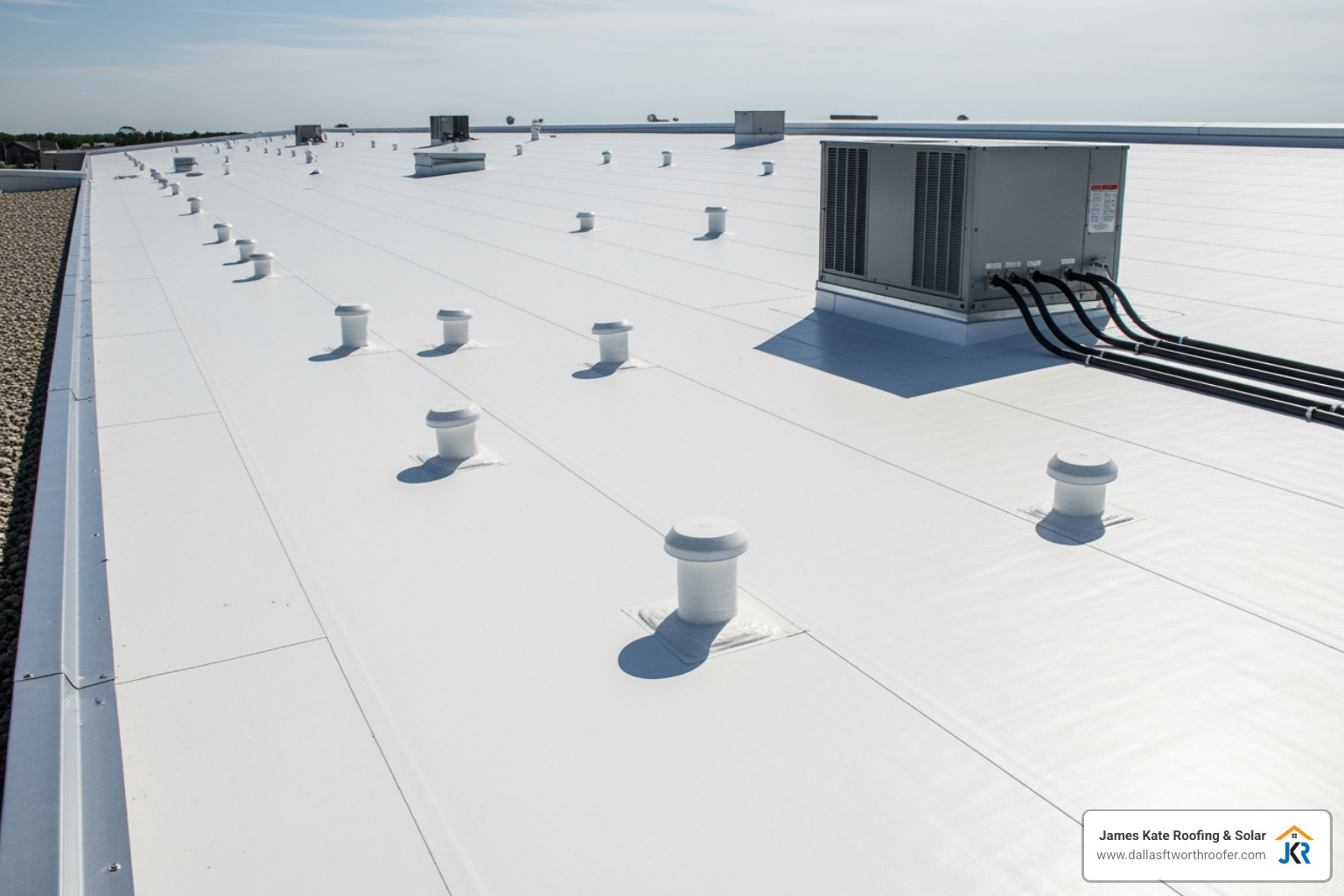

Understanding the Anatomy of a Commercial Roof System

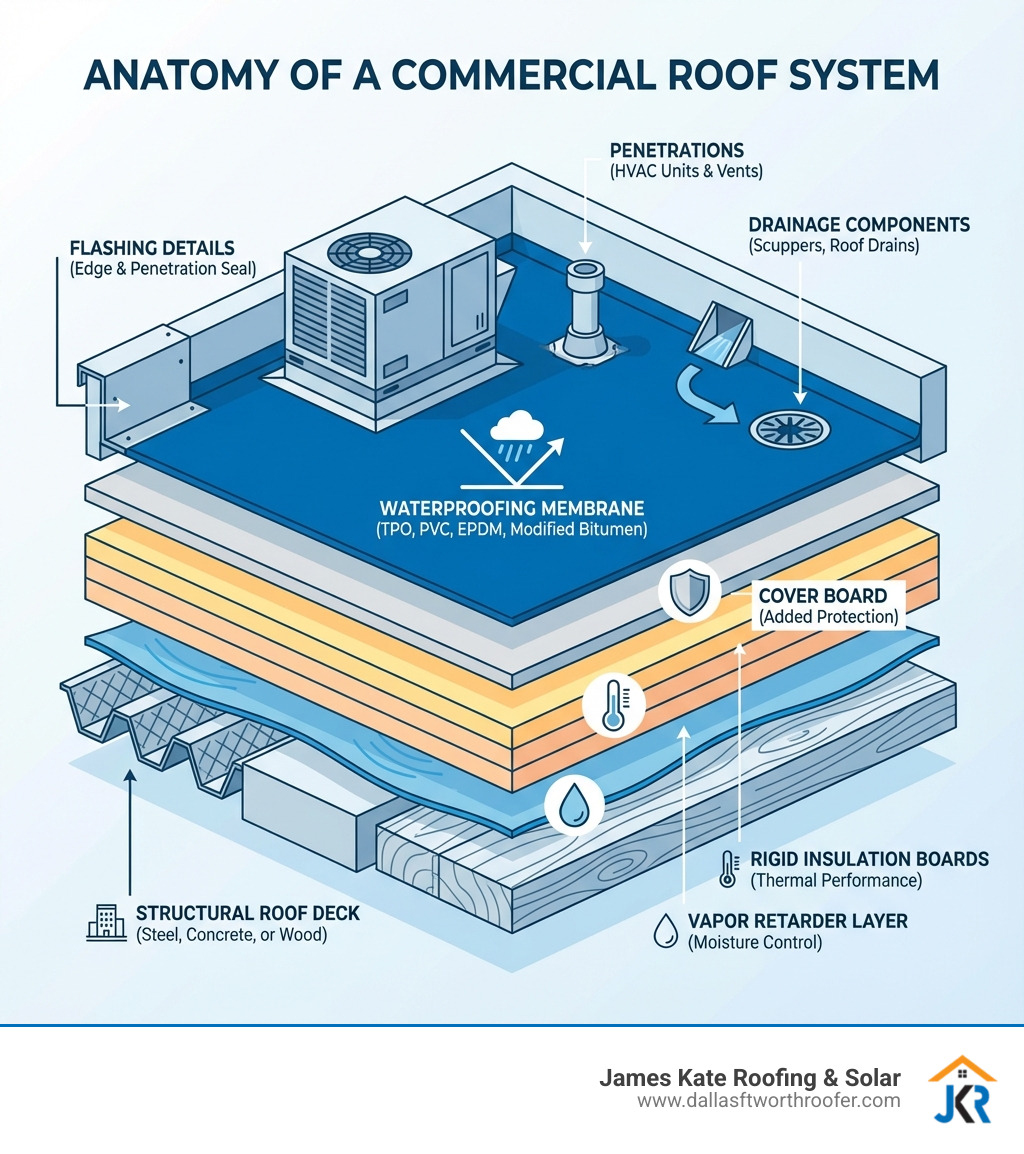

Every commercial roof, regardless of its specific type, is a complex system designed to keep your building dry and efficient. Think of it as a carefully constructed shield, each layer playing a vital role. From the structural deck to the outermost membrane, insulation, cover boards, drainage, flashing, and penetrations all work in harmony. Understanding these components is the first step to making informed decisions about your commercial roof.

The Basic Components of a Commercial Roof System

The Core Components

At the heart of any commercial roof is the roof deck. This is the structural foundation, supporting the entire roofing system and anything placed on it, like HVAC units or solar panels. Common types include:

- Steel Deck: Popular in commercial buildings due to its durability, strength, and fire resistance.

- Concrete Deck: Often used for larger commercial or industrial buildings, known for its immense strength and superior fire resistance.

- Wood Deck: Including plywood or OSB, often found in smaller commercial structures or older buildings.

- Tectum Deck: A unique material popular for its sound absorption and insulation capabilities, often seen in auditoriums, churches, and school gyms.

Above the deck, insulation is crucial for thermal performance. It blocks heat loss in winter and heat intrusion in summer, directly impacting your energy bills. The R-value of your insulation—its resistance to heat flow—is a key factor in your building’s energy efficiency. We know that insulation can turn your roof from a net cost into a net savings by significantly reducing energy consumption.

Sometimes, we add a cover board on top of the insulation. While not always essential, it significantly increases the durability of the roofing system, offering protection from hail strikes, foot traffic, and fire. It’s especially useful when installing a new roof over an existing one, providing a smooth, stable surface.

The Weatherproofing Layer: Membranes and More

The roof membrane is the outermost layer, your building’s first line of defense against the elements. It’s the primary waterproofing component, shielding your property from rain, snow, wind, hail, and damaging UV rays.

However, a membrane alone isn’t enough. Flashing and edge details are critical for sealing off and protecting vulnerable areas. These include:

- Coping Caps: Protect parapet walls, preventing water from seeping into the wall structure.

- Drip Edges: Installed along the perimeter to prevent water from seeping underneath the roof edge and damaging fascia.

Roof penetrations are any elements that pass through the roof, such as HVAC units, vents, pipes, and skylights. Each penetration creates a potential weak point for leaks. Proper sealing with specialized flashing around these areas is absolutely essential to maintain watertight integrity. We pay meticulous attention to these details, because even a small oversight can lead to big problems down the road.

Asphaltic Systems: BUR vs. Modified Bitumen

Asphaltic systems have a long history in commercial roofing.

Built-Up Roofing (BUR), often called “tar and gravel” roofs, has been a popular choice for over a century. It’s constructed by alternating layers of asphalt-saturated felts (or “plies”) with layers of hot asphalt, topped with a layer of gravel or crushed stone. A four-ply BUR system means four layers of membrane. BUR systems are known for their robust protection and excellent waterproofing capabilities.

Modified Bitumen (Mod Bit) is a more modern evolution of asphaltic roofing. It’s essentially asphalt that has been “modified” with polymers to improve its flexibility, durability, and waterproofing characteristics. There are two main types of modifiers:

- APP (Atactic Polypropylene): Gives the membrane plastic-like properties, making it more rigid and easier to torch-apply.

- SBS (Styrene Butadiene Styrene): Provides rubber-like elasticity, making the membrane more flexible and resistant to temperature fluctuations, often installed with hot asphalt or cold adhesives.

The key differences between BUR and Mod Bit lie in their composition and installation. BUR is built up on-site with multiple layers of felt and hot asphalt, while Mod Bit typically comes in factory-manufactured rolls that are then applied as a two- or three-ply system. Installation methods for Mod Bit include heat welding (torch-down), hot mopping, cold applied adhesives, or self-adhered sheets. Modified bitumen roofing has an average lifespan of 20 years, and can last even longer with basic care and maintenance, making it one of the strongest commercial roofing systems available.

More info about tar and gravel roofs

Choosing Your Material: A Comparison of Popular Systems

Selecting the right material for your commercial roof is a big decision, impacting everything from initial cost to long-term performance and energy efficiency. It’s not a one-size-fits-all answer; what works best for one building in Dallas might not be ideal for another in Granbury.

When we help building owners choose, we consider several critical factors:

- Cost: Both upfront installation and long-term maintenance.

- Durability: How well it withstands weather, foot traffic, and potential impacts.

- Climate: The extreme heat of Texas summers, occasional freezes, and severe storms.

- Building Type: The structure’s purpose, size, and existing deck.

- Foot Traffic: If the roof will be accessed frequently for maintenance or equipment.

- Energy Goals: Desire for reflective surfaces to reduce cooling costs or support for solar panels.

Here’s a quick comparison of some of the most popular commercial roofing materials:

| Material | Typical Lifespan (Years) | Durability Rating (1-5, 5=highest) | Energy Efficiency (1-5, 5=highest) | Relative Cost (1-5, 5=highest) |

|---|---|---|---|---|

| TPO | 20+ | 4 | 4 | 3 |

| PVC | 20-30+ | 5 | 5 | 4 |

| EPDM | 20-30 | 3 | 2 (black absorbs heat) | 2 |

| Modified Bitumen | 20 | 4 | 3 | 3 |

Single-Ply Membranes: The Modern Standard

Single-ply membranes are flexible sheets of compounded synthetic materials, manufactured to strict quality control requirements. They provide strength, flexibility, and long-lasting durability. The Single Ply Roofing Industry (SPRI) classifies these as either thermosets (like EPDM) or thermoplastics (like TPO and PVC).

-

TPO Roofing (Thermoplastic Polyolefin): TPO is currently the low-slope market leader, garnering a 40 percent share of the new construction market and 30 percent of the reroofing market. It’s a durable single-ply material resistant to UV, ozone, and chemical exposure. TPO roofs can last 20+ years with the right maintenance plan, performing well in harsh environments. They are highly heat resistant, which helps keep heating and cooling costs down, a big plus for DFW businesses. We’ve seen TPO alone make up 40% of commercial flat roofs in our area.

- Advantages: Excellent heat reflectivity (especially white TPO), energy-efficient, strong, UV resistant, puncture resistant, relatively easy to install.

- Disadvantages: Seam integrity can be compromised if not installed correctly (though modern welding techniques mitigate this).

-

PVC Roofing (Polyvinyl Chloride): Introduced in the 1970s, PVC membranes can offer guarantees up to 30 years. PVC is highly resistant to chemicals, grease, and punctures, making it ideal for restaurants or industrial facilities. Its weldable seams provide a strong, verifiable bond.

- Advantages: Superior chemical and grease resistance, strong weldable seams, excellent puncture resistance, highly reflective, long lifespan.

- Disadvantages: Generally higher initial cost compared to TPO or EPDM.

-

EPDM Roofing (Ethylene Propylene Diene Monomer): EPDM is a durable rubber roofing solution, capturing 22 percent of market share for new construction and 26 percent of the reroofing market. It’s known for being very durable, less expensive than TPO, and easier to install and repair. EPDM is resistant to weather and sunlight, and it’s available in both black and white.

- Advantages: Very durable, cost-effective, easy to repair, resistant to weather and UV.

- Disadvantages: Typically black, meaning it absorbs more heat, which can increase cooling costs in hot climates like Texas.

Other Primary Types of Commercial Roof Systems

While single-ply membranes dominate the market, other systems offer unique benefits:

-

Metal Roofing: One of the world’s oldest roofing systems, metal roofs are known for their exceptional durability and longevity, often lasting up to 40 years. Most commercial metal roofs are made of corrugated galvanized steel. They are tough, very long-lasting, fire-resistant, and lightweight, making them durable in severe weather. Standing seam metal roofing is a popular choice for low-slope structural applications.

- Advantages: Extremely long lifespan, fire-resistant, low maintenance, excellent wind resistance, recyclable.

- Disadvantages: Higher initial cost, can be noisy during rain, potential for dents.

More info about metal roofing

-

Liquid-Applied Membranes (Roof Coatings): These are increasingly popular for restoring aging roofs and improving energy efficiency. Applied as a fluid, they cure to form a seamless, monolithic membrane over an existing roof. This can extend the roof’s lifespan, delay costly tear-offs, and improve waterproofing.

- Advantages: Cost-effective restoration, seamless, lightweight, improves energy efficiency, produces little waste.

- Disadvantages: Requires a structurally sound existing roof, proper surface preparation is critical.

More info about roof coatings

Installation and Performance: Key Factors for a Durable Commercial Roof

A great commercial roof isn’t just about the materials; it’s profoundly influenced by the installation process. The way a system is attached, the quality of insulation, and adherence to local building codes all play a monumental role in its long-term performance and durability. We believe in getting it right the first time, every time.

More info about roof installation

How Attachment Methods Impact Performance

The method used to attach the roofing membrane to the deck significantly affects its resistance to wind uplift and overall performance:

-

Fully Adhered Systems: The membrane is glued directly to the substrate (insulation or cover board) using an adhesive.

- Pros: Excellent wind uplift resistance, smooth aesthetic, no punctures to the membrane.

- Cons: Higher labor costs due to adhesive application, temperature-sensitive installation.

-

Mechanically Attached Systems: The membrane is fastened to the roof deck using screws and plates.

- Pros: Cost-effective, good for lighter deck types, less weather-dependent installation.

- Cons: Requires penetrations through the membrane (which must be properly sealed), visible fasteners or plates.

-

Ballasted Systems: The membrane is loosely laid over the insulation and held in place by the weight of gravel or pavers.

- Pros: Cost-effective, simple to install, good thermal mass.

- Cons: Requires a roof deck that can withstand significant structural load, not recommended for high-wind or hurricane-prone regions (like parts of Texas during severe storms), difficult to inspect for leaks.

The Role of Insulation and Cover Boards

We’ve touched on insulation, but let’s dive a little deeper. Its primary purpose is to provide thermal resistance (R-value), which directly translates to lower heating and cooling costs for your business. In the scorching Texas summers, good insulation is your best friend.

Common types of insulation include:

- Polyisocyanurate (Polyiso): As highlighted by the Polyisocyanurate Manufacturers Association (PIMA), polyiso is a widely used, cost-effective, and high-performance insulation product.

- EPS (Expanded Polystyrene): Lightweight and moisture-resistant.

- XPS (Extruded Polystyrene): Offers higher compressive strength and moisture resistance than EPS.

Beyond energy savings, insulation and cover boards also contribute to fire rating compliance and protect the roof from foot traffic and hail damage. A robust insulation and cover board layer can be the unsung hero, significantly extending your roof’s life and saving you money.

Navigating Local Building Codes and Regulations

Local building codes and regulations in the DFW area heavily influence the choice of commercial roofing materials and installation requirements. These codes are designed to ensure public safety and building performance. They dictate:

- Material Choice: Certain materials may be restricted or mandated based on building type, location, or fire safety requirements.

- Installation Requirements: Specific fastening patterns, flashing details, and wind uplift resistance standards are often prescribed.

- Wind-Speed Zones: Texas, being prone to high winds and severe weather, has specific requirements for wind uplift resistance, particularly at roof edges and corners. Our installations always account for these critical zones.

- Fire Ratings: Buildings in specific areas or with certain occupancies may require Class A fire-rated roof coverings.

Working with a knowledgeable and licensed contractor is paramount to ensure your commercial roof meets all local codes and regulations, avoiding costly penalties and ensuring the safety of your investment. We pride ourselves on staying up-to-date with all local requirements. You can find a licensed roofing contractor through reputable industry associations.

Protecting Your Investment: Maintenance, Warranties, and Replacement

Your commercial roof is a significant investment. Just like any other valuable asset, it requires proactive care to extend its lifespan, prevent unexpected issues, and avoid costly damage. Think of it as a marathon, not a sprint—regular attention ensures it crosses the finish line strong.

The Importance of Regular Maintenance and Inspection

The greatest cause of premature problems on flat roofs is the failure to find and correct minor defects in their early stages. That’s why regular maintenance and inspection are non-negotiable.

Benefits of preventative maintenance include:

- Extending Lifespan: Proactive repairs address small issues before they become major, delaying costly replacements.

- Cost Savings: Prevents expensive water damage to your building’s interior and contents.

- Warranty Compliance: Many manufacturer warranties require regular inspections and maintenance.

A typical inspection checklist involves:

- Debris Removal: Clearing leaves, branches, and trash that can impede drainage.

- Drain Cleaning: Ensuring scuppers and drains are free-flowing to prevent ponding water.

- Seam Inspection: Checking for any signs of separation or cracking in the membrane seams.

- Flashing Checks: Inspecting around penetrations, parapet walls, and edges for wear or damage.

We recommend detailed roof inspections at least once a year, and especially after any major weather event that rolls through DFW.

Commercial Roof Inspection & Maintenance Guide

More info about roof maintenance

Signs Your Commercial Roof Needs Attention

Knowing when your commercial roof needs repair or even replacement can save you a lot of headaches and money. Here are some common warning signs:

- Ponding Water: Water that stands on your roof for more than 48 hours is a major red flag, indicating drainage issues or structural sagging.

- Blisters or Bubbles: Swelling in the membrane can indicate trapped moisture or delamination.

- Cracked or Separated Seams: These are direct pathways for water intrusion.

- Interior Water Stains: Stains on ceilings or walls are obvious signs of a leak.

- Rising Energy Costs: An aging or damaged roof can lose its insulating properties, leading to skyrocketing utility bills.

- Moss or Algae Growth: While seemingly harmless, this can signal dampness and degrade the roofing material over time.

- Age: Most commercial roofs have an expected lifespan. If yours is nearing or exceeding it (e.g., TPO roofs can last 20+ years, modified bitumen 20 years), it’s time for an assessment.

If you notice any of these signs, it’s crucial to act quickly. Ignoring them can lead to extensive damage, business disruption, and premature replacement.

Understanding Commercial Roof Warranties

Warranties provide crucial protection for your commercial roof investment. It’s vital to understand what they cover and for how long. There are generally two types:

- Manufacturer’s Warranty: This covers defects in the roofing material itself. Coverage can vary widely, but often ranges from 5 to 25 years.

- Workmanship Warranty: This covers the quality of the installation. We are proud to offer up to a 25-year workmanship warranty, backed by our GAF President’s Club recognition, ensuring our installations meet the highest standards.

Some comprehensive options include NDL (No Dollar Limit) warranties, which cover the cost of materials and labor to repair or replace a defective roof system without a monetary cap. The length of coverage can range from 5 to 25 years, or even longer for some premium systems. Always remember that proper installation by a certified contractor is often a prerequisite for a valid manufacturer’s warranty.

warranties and why they are important

Modern Roofing Solutions: Sustainability, Solar, and Financing

The world of commercial roofing is constantly evolving, with new technologies and approaches emerging to meet demands for sustainability, energy independence, and financial flexibility. We’re excited to help DFW businesses accept these future-forward solutions.

Sustainable and ‘Green’ Roofing Options

Sustainable roofing isn’t just a trend; it’s a smart business decision with environmental and financial benefits.

- Cool Roofs: These roofs are designed to reflect more sunlight and absorb less heat than standard roofs. This reflectivity and thermal emissivity (the ability to radiate absorbed heat) significantly reduce the heat island effect and lower cooling costs. White TPO and PVC membranes are excellent examples of cool roof materials, often EnergyStar certified. The Cool Roof Rating Council provides valuable data on roof surface performance.

- Vegetative or ‘Green’ Roofs: Also known as living roofs, these systems involve planting vegetation on a suitable flat roof. Green roofs can be “intensive” (deep soil, diverse plants), “semi-intensive,” or “extensive” (shallow soil, largely self-sustaining plants). They offer numerous benefits:

- Stormwater Management: Absorb rainwater, reducing runoff and strain on drainage systems.

- Reduced Urban Heat Island Effect: Cool down urban areas, improving air quality.

- Energy Savings: Provide natural insulation, reducing heating and cooling needs.

- Ecological Benefits: Create habitats for local wildlife and contribute to healthy ecosystems.

- Potential Grants: Government grants may be available for green roof projects.

Green Roofs for Healthy Cities is a great resource for learning more.

Key Considerations for Commercial Roof Solar Panel Installation

Integrating solar panels onto your commercial roof is an excellent way to achieve energy independence and reduce your carbon footprint. However, it requires careful planning:

- Structural Capacity: Can your existing roof deck support the added weight of solar panels and their racking? A structural engineer’s assessment is crucial.

- Roof Condition: Your roof needs to be in excellent condition, capable of lasting as long as your solar array (typically 20-25+ years). It doesn’t make sense to put new solar panels on an old, failing roof.

- Membrane Compatibility: Ensure the roofing membrane is compatible with the solar racking system and won’t be damaged during installation.

- Attachment Methods: We use rack-mounted solar systems that minimize penetrations and ensure the roof’s integrity.

- Warranty Implications: It’s essential to coordinate with your roofing contractor and solar installer to ensure your roof warranty remains intact after solar installation.

- ROI Calculation: The price of electricity generation is easily calculated, making solar a secure investment with low maintenance costs.

More info about rack-mounted solar

Innovations and Financing Your Project

The commercial roofing industry is constantly innovating. We’re seeing exciting advancements like:

- Drones for Inspections: Offering safer, faster, and more detailed roof inspections.

- Advanced Material Formulations: Leading to more durable, energy-efficient, and sustainable membranes and coatings.

- Smart Roofing Sensors: Embedded sensors that can monitor moisture levels, temperature, and even detect leaks early.

We understand that a commercial roof replacement or major repair is a significant capital expenditure. That’s why we offer financing options to help DFW businesses manage costs effectively, spreading payments over time and preserving your working capital. We believe in transparent, no-hidden-cost solutions.

Conclusion

Choosing, installing, and maintaining a commercial roof is a complex but crucial process that directly impacts your business’s bottom line and operational continuity. By making informed decisions about materials, understanding installation nuances, prioritizing regular maintenance, and exploring modern solutions like sustainability and solar integration, you’re not just protecting a building; you’re safeguarding your entire operation.

We believe in providing long-term value and protecting your asset with honesty and integrity. As a family-owned DFW company, James Kate Roofing & Solar is committed to top-tier roofing and solar services, backed by GAF President’s Club recognition and up to a 25-year workmanship warranty. We’re here to be your trusted partner, ensuring your commercial roof performs optimally for decades to come.